Commissioning a can, bowl, or bottle sealing machine is a crucial step in streamlining production processes across a wide range of industries. This process ensures that every sealer machine operates with precision, consistency, and maximum efficiency, laying the foundation for reliable, high-quality output.

At Asia Supply, we provide can, bowl, and bottle sealers along with comprehensive commissioning services to guarantee seamless performance from day one. Our skilled professionals fine-tune machine settings, conduct repeated performance tests, and troubleshoot potential issues to ensure every machine aligns perfectly with our clients’ production requirements.

This meticulous approach results in enhanced operational efficiency, reduced material wastage, and greater overall productivity — benefits that directly support our customers’ success.

In essence, commissioning is not just a setup — it’s a quality assurance process that ensures your sealing machines deliver reliable, efficient, and safe performance. With Asia Supply, you can be confident that your can, bowl, and bottle sealers will help you maintain top-tier product quality while optimizing your production workflow.

.png)

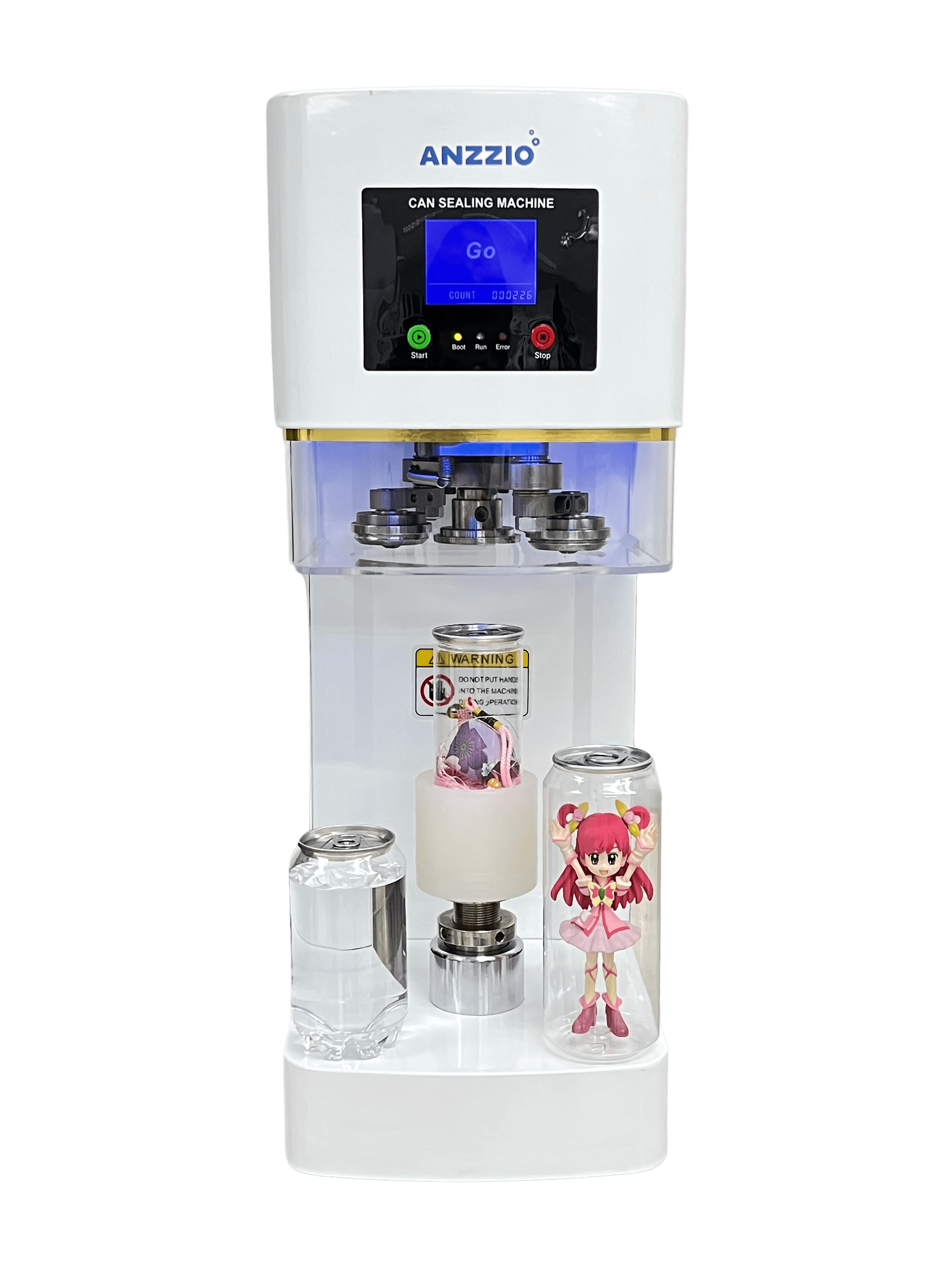

Yes, separate sealing machines are used for cans, bowls, and bottles as each requires different lid sizes and sealing configurations to ensure proper sealing performance.

All sealing machines come with a 1-year warranty covering manufacturing defects (excluding normal wear and tear). Our team also provides technical support and assistance for any defect-related issues to ensure smooth operation.

Yes, the commissioning service is included in the purchase price of the sealing machine — no additional fees are required.

Commissioning includes onsite setup, live demonstration, and machine tuning to ensure optimal performance. The machine is plug-and-play, so no additional training is needed.

The commissioning timeline depends on stock availability. If the machine is in stock, installation and commissioning can be completed on the same day.