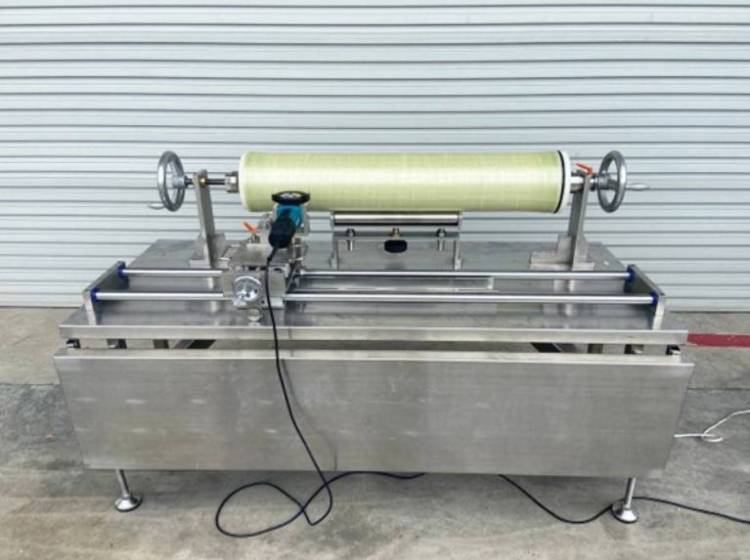

At Asia Supply, we provide customized fabrication services tailored to your unique needs — including our RO Membrane Autopsy Table. This specialized table allows you to dissect and analyze RO membranes used in your operations.

With its extendable design, you can perform a thorough investigation to identify fouling, scaling, biofilm formation, or physical damage that may have occurred during the membrane’s operational life.

By leveraging this tool, you can ensure your water treatment systems consistently deliver high-quality water efficiently, making the RO Memopsy Table an indispensable asset for water purification and desalination across industries.

Keep your water systems performing at their best with Asia Supply’s innovative solutions!

Our RO Membrane Autopsy Table is a specially fabricated work‑table designed to dissect and examine reverse osmosis (RO) membranes that have been in operation. It allows you to perform detailed investigations into fouling, scaling, biofilm formation, or physical damage.

By using the table to analyze your used membranes, you gain insights into the root causes of performance degradation. This helps you optimize maintenance, cleaning regimes, and replacement schedules — ensuring your water treatment or desalination system continues delivering high‑quality water efficiently.

Yes — we offer custom fabrication services, so the table can be tailored in terms of size, extension length, materials, and other features to match your operational setup or laboratory space.

While features will depend on your customization, the table supports an extendable work surface, and is built to enable full membrane sectioning and visual/physical inspection of all parts of the membrane module (e.g., element, spacer, feed end, permeate end, etc.).

It is suitable for a wide range of industries that deploy RO systems — for example: water purification, desalination, wastewater reuse, industrial process water, pharmaceuticals, electronics, chemical processing, and more.

The table helps you save on downtime, extend membrane life, reduce unexpected failures and optimize your cleaning/maintenance strategy. In short — better performance, fewer surprises, and improved system efficiency.

Once the specifications are finalized (size, layout, work surface, etc.), we will provide a fabrication timeline. We also support installation and commissioning so the table is properly fitted into your lab or maintenance area.